펀칭 기계Bobst

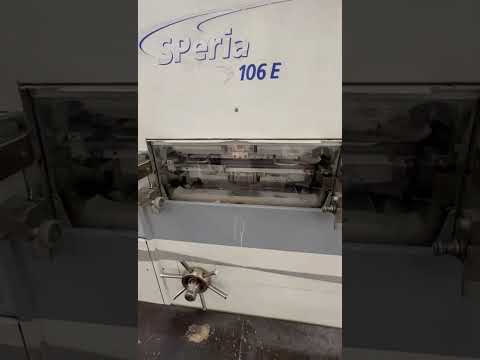

Autoplatine Speria 106 E

펀칭 기계

Bobst

Autoplatine Speria 106 E

제조 연도

2006

상태

중고

위치

Hlavní město Praha

사진은 보여줍니다

지도 표시

기계 정보

가격 및 위치

- 위치:

- Jezkova 1054/10, 13000 Praha 3, Česká republika

전화하기

제안 세부 정보

- 광고 ID:

- A20248585

- 업데이트:

- 마지막 업데이트: 08.12.2025

설명

Bobst Autoplatine Speria 106 E

STANDARD EQUIPMENT

MACHINE

- Centerline system for quick job changeover.

- Electronic sheet travel monitoring system.

- Adjustable centering at the stripping station.

- Control cabinet air conditioning unit.

- Bobst electronic control system C.U.B.E. (Control Unit Bobst Electronic).

This microprocessor-based Bobst system allows the operator to easily manage, visualize, and monitor the machine’s various functions and components.

- Main motor with frequency inverter control.

Bodpfexl Talsx Ah Djcw

FEEDER

- Pile tray with handle for easy manual lateral alignment during production.

- Synchronization device ensuring proper sheet arrival to the front lays when the machine is stopped.

- Automatic pile lifting controlled by pressing foot.

- Rear pile guides (operator side and opposite operator side).

- Adjustable side blowers with Centerline markings.

- Suction unit.

FEED TABLE

- Feed table with anti-static stainless steel covering.

- Feed table entrance equipped with lateral ramps.

- Four front lays, pairwise adjustable, with front register control.

- "Pull" guide (operator side), adjustable with Centerline markings and side register control.

- Double sheet detector.

- Support plates at platen station entry.

- Sheet hold-down mechanism (guides sheets to front lays).

- Upper frame with manual lifting device.

- Upper transport system for paper, paperboard, and corrugated board.

- Transport belts with lateral guides and automatic tensioning system.

PLATEN

- Gripper reopening device.

- Centering and locking for equipment.

- Locking the chase to the upper beam.

- Cutting force measurement with strain gauge.

1 synthetic supporting plate.

1 upper chase: fixed bottom plate.

1 cutting plate.

WASTE STRIPPING STATION

- Air-cylinder-driven upper frame lifting.

1 upper pull-out frame (with crossbars and clamps).

1 lower pull-out frame.

DELIVERY

- Pile tray.

- Front jogger.

- Adjustable rear and side joggers with Centerline markings.

- Braking brush.

- Manual non-stop rack.

AVAILABLE EXTRAS

B MACHINE

1 B-1 Raised machine base

C FEEDER

1 C-4 Manual non-stop device

E PLATEN

1 E-5 Compensating plate

1 E-55 Micro-adjustable supporting plate centering

F WASTE STRIPPING STATION

1 F-31 Quick-lock device for the upper pull-out frame

이 광고는 자동으로 번역되었습니다. 번역 오류가 있을 수 있습니다.

STANDARD EQUIPMENT

MACHINE

- Centerline system for quick job changeover.

- Electronic sheet travel monitoring system.

- Adjustable centering at the stripping station.

- Control cabinet air conditioning unit.

- Bobst electronic control system C.U.B.E. (Control Unit Bobst Electronic).

This microprocessor-based Bobst system allows the operator to easily manage, visualize, and monitor the machine’s various functions and components.

- Main motor with frequency inverter control.

Bodpfexl Talsx Ah Djcw

FEEDER

- Pile tray with handle for easy manual lateral alignment during production.

- Synchronization device ensuring proper sheet arrival to the front lays when the machine is stopped.

- Automatic pile lifting controlled by pressing foot.

- Rear pile guides (operator side and opposite operator side).

- Adjustable side blowers with Centerline markings.

- Suction unit.

FEED TABLE

- Feed table with anti-static stainless steel covering.

- Feed table entrance equipped with lateral ramps.

- Four front lays, pairwise adjustable, with front register control.

- "Pull" guide (operator side), adjustable with Centerline markings and side register control.

- Double sheet detector.

- Support plates at platen station entry.

- Sheet hold-down mechanism (guides sheets to front lays).

- Upper frame with manual lifting device.

- Upper transport system for paper, paperboard, and corrugated board.

- Transport belts with lateral guides and automatic tensioning system.

PLATEN

- Gripper reopening device.

- Centering and locking for equipment.

- Locking the chase to the upper beam.

- Cutting force measurement with strain gauge.

1 synthetic supporting plate.

1 upper chase: fixed bottom plate.

1 cutting plate.

WASTE STRIPPING STATION

- Air-cylinder-driven upper frame lifting.

1 upper pull-out frame (with crossbars and clamps).

1 lower pull-out frame.

DELIVERY

- Pile tray.

- Front jogger.

- Adjustable rear and side joggers with Centerline markings.

- Braking brush.

- Manual non-stop rack.

AVAILABLE EXTRAS

B MACHINE

1 B-1 Raised machine base

C FEEDER

1 C-4 Manual non-stop device

E PLATEN

1 E-5 Compensating plate

1 E-55 Micro-adjustable supporting plate centering

F WASTE STRIPPING STATION

1 F-31 Quick-lock device for the upper pull-out frame

이 광고는 자동으로 번역되었습니다. 번역 오류가 있을 수 있습니다.

이 광고들도 당신에게 관심이 있을 수 있습니다.

소형 광고

Leinfelden-Echterdingen

Leinfelden-Echterdingen

8,835 km

FGT 그래픽 기계 - DigitalPress

Konica Minolta6120

Konica Minolta6120

소형 광고

Alkmaar

Alkmaar

8,742 km

펀칭기계

KAMAProcut 58

KAMAProcut 58

소형 광고

독일

독일

8,579 km

가방 만드는 기계

Honsel & Co.722

Honsel & Co.722

소형 광고

София

София

8,416 km

오프셋 인쇄기

HeidelbergSM 74 5 P2 L

HeidelbergSM 74 5 P2 L

소형 광고

독일

독일

8,579 km

2가지 색상

HeidelbergSM 52-2

HeidelbergSM 52-2

소형 광고

Henstedt-Ulzburg

Henstedt-Ulzburg

8,408 km

종이 절단기

PolarN 115 PLUS

PolarN 115 PLUS

소형 광고

슬로베니아

슬로베니아

8,729 km

오프셋 판 처리기

Glunz & JensenTiger 125 Premium

Glunz & JensenTiger 125 Premium

소형 광고

Alsfeld

Alsfeld

8,672 km

자동 펀칭기

BobstSP142ER

BobstSP142ER

소형 광고

Valea Mare-Podgoria

Valea Mare-Podgoria

8,169 km

오프셋 인쇄기

MAN Roland704

MAN Roland704

소형 광고

Wuppertal

Wuppertal

8,736 km

테이프 직조기 4/42mm

Jakob Müller Frick AGNF42 4/42mm

Jakob Müller Frick AGNF42 4/42mm

귀하의 광고가 성공적으로 삭제되었습니다

오류가 발생했습니다