브러시 샌더DANIBRUM

DAS LDX 1000 - 6

브러시 샌더

DANIBRUM

DAS LDX 1000 - 6

제조 연도

2025

상태

신규

위치

Vermești

사진은 보여줍니다

지도 표시

기계 정보

가격 및 위치

- 위치:

- Strada Combinatului, Bacău 605200, România

전화하기

제안 세부 정보

- 광고 ID:

- A19072501

- 업데이트:

- 마지막 업데이트: 05.05.2025

설명

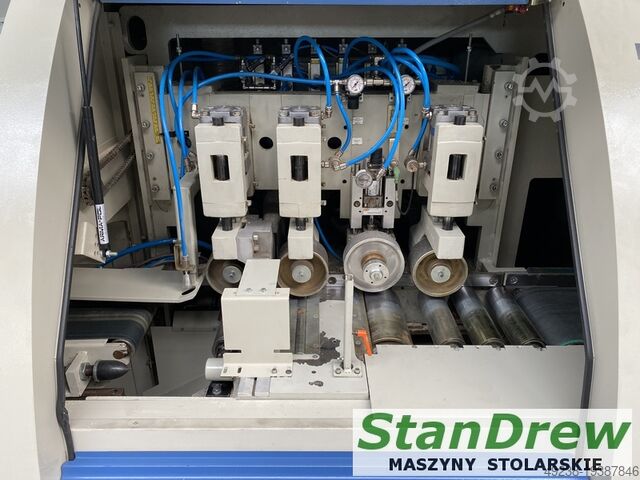

Improve the quality of your finish with the DAS LDX 1000 – 6 brush sander

The DAS LDX 1000 – 6 automatic machine is designed for precise sanding and finishing of profiled wood or MDF elements, offering excellent results even for the most demanding aesthetic requirements. It is ideal for smoothing, fine sanding and final preparation of surfaces, thanks to the versatile and robust configuration of the 6 working units.

Standard features and technical characteristics:

Multiple working units: oscillating longitudinal drums, oscillating pads, transverse drums with Ø 280 mm and width 1000 mm, equipped with 20 helically mounted brushes.

Working capacity: max. width 1000 mm, workpiece thickness max. 100 mm.

Efficient sanding: disc rotation speed between 50 – 300 RPM (adjustable via frequency inverter).

Sanding brushes: adjustable length between 20 – 70 mm, allowing detailed work on profiles with a depth of up to 8 mm.

Touchscreen control panel: Ergonomically positioned, it allows independent control of each unit. The interface is intuitive, developed by DANIBRUM engineers for fast and efficient operation.

Adherent conveyor belt: Equipped with ribbed rubber for constant advance, driven by a 1.1 kW motor. Includes automatic centering roller, height adjustment sensor and brushes for dust removal at the entrance and exit.

Professional sliding system: Based on recirculating ball bearings, it offers precise, reliable and low-maintenance movement. Lubrication is done manually.

Oscillation for sanding units: Ensures uniform finishing and prolongs the life of abrasive belts and sisal brushes.

Efficient exhaust system: Each group has dedicated exhaust ports, connected to 8 Ø 100 mm outlets, keeping the work area clean and efficient.

Fast side access: Large side openings allow easy brush changes and quick access for maintenance.

Toothed belt transmission: Ensures constant speeds, stable transmission and low noise level during operation.

Flexibility in finishing: The "fast release" system allows for quick changes of belts and brushes. The adaptable configuration is suitable for various styles and types of finishing.

The DAS LDX 1000 – 6 machine is an efficient solution for manufacturers who want superior quality in the processing of profiled wood elements, with high productivity and impeccable finishing.

Maximum working width

1000 mm

Maximum working height

100 mm

Longitudinal drum diameter (Ø)

220 mm

Longitudinal drum drive motor power - oscillating

2 x 1.5 kW

Longitudinal drum oscillation motor power

0.55 kW

Oscillating pad diameter

200 mm

Oscillating pad drive motor power

1.5 kW

Pad oscillation motor power

0.18 kW

Transverse drum diameter (Ø)

280 mm

Transverse drum drive motor power

2 x 2.2 kW

Advance motor power

1.1 kW

Brush speed

max. 1000 rpm

Exhaust hood diameter (Ø)

4 x 100 mm

Overall dimensions

3300 x 1600 mm

Weight

1500 kg

Cpodpfx Abowhbtzs Rjw

Technical support available in Romanian, English or German.

이 광고는 자동으로 번역되었습니다. 번역 오류가 있을 수 있습니다.

The DAS LDX 1000 – 6 automatic machine is designed for precise sanding and finishing of profiled wood or MDF elements, offering excellent results even for the most demanding aesthetic requirements. It is ideal for smoothing, fine sanding and final preparation of surfaces, thanks to the versatile and robust configuration of the 6 working units.

Standard features and technical characteristics:

Multiple working units: oscillating longitudinal drums, oscillating pads, transverse drums with Ø 280 mm and width 1000 mm, equipped with 20 helically mounted brushes.

Working capacity: max. width 1000 mm, workpiece thickness max. 100 mm.

Efficient sanding: disc rotation speed between 50 – 300 RPM (adjustable via frequency inverter).

Sanding brushes: adjustable length between 20 – 70 mm, allowing detailed work on profiles with a depth of up to 8 mm.

Touchscreen control panel: Ergonomically positioned, it allows independent control of each unit. The interface is intuitive, developed by DANIBRUM engineers for fast and efficient operation.

Adherent conveyor belt: Equipped with ribbed rubber for constant advance, driven by a 1.1 kW motor. Includes automatic centering roller, height adjustment sensor and brushes for dust removal at the entrance and exit.

Professional sliding system: Based on recirculating ball bearings, it offers precise, reliable and low-maintenance movement. Lubrication is done manually.

Oscillation for sanding units: Ensures uniform finishing and prolongs the life of abrasive belts and sisal brushes.

Efficient exhaust system: Each group has dedicated exhaust ports, connected to 8 Ø 100 mm outlets, keeping the work area clean and efficient.

Fast side access: Large side openings allow easy brush changes and quick access for maintenance.

Toothed belt transmission: Ensures constant speeds, stable transmission and low noise level during operation.

Flexibility in finishing: The "fast release" system allows for quick changes of belts and brushes. The adaptable configuration is suitable for various styles and types of finishing.

The DAS LDX 1000 – 6 machine is an efficient solution for manufacturers who want superior quality in the processing of profiled wood elements, with high productivity and impeccable finishing.

Maximum working width

1000 mm

Maximum working height

100 mm

Longitudinal drum diameter (Ø)

220 mm

Longitudinal drum drive motor power - oscillating

2 x 1.5 kW

Longitudinal drum oscillation motor power

0.55 kW

Oscillating pad diameter

200 mm

Oscillating pad drive motor power

1.5 kW

Pad oscillation motor power

0.18 kW

Transverse drum diameter (Ø)

280 mm

Transverse drum drive motor power

2 x 2.2 kW

Advance motor power

1.1 kW

Brush speed

max. 1000 rpm

Exhaust hood diameter (Ø)

4 x 100 mm

Overall dimensions

3300 x 1600 mm

Weight

1500 kg

Cpodpfx Abowhbtzs Rjw

Technical support available in Romanian, English or German.

이 광고는 자동으로 번역되었습니다. 번역 오류가 있을 수 있습니다.

이 광고들도 당신에게 관심이 있을 수 있습니다.

소형 광고

Ludwigsstadt

Ludwigsstadt

8,583 km

브러시 디버링 기계

WeberTTS-1100

WeberTTS-1100

소형 광고

Scerne

Scerne

9,009 km

수직 패널 톱

Putsch MeniconiUniver

Putsch MeniconiUniver

소형 광고

루마니아

루마니아

8,097 km

적재 및 하역 기능이 있는 CNC 네스팅 머신

NanxingNCG3021L

NanxingNCG3021L

소형 광고

Egenhofen

Egenhofen

8,760 km

브러싱 머신, 샌딩 머신

- ItalyAdvance ROTOR 600.4 / Special 5

- ItalyAdvance ROTOR 600.4 / Special 5

소형 광고

Nattheim

Nattheim

8,776 km

페인트 미스트 추출 벽

HöckerPaint Star 3500

HöckerPaint Star 3500

소형 광고

Egenhofen

Egenhofen

8,760 km

스위블 스핀들 밀링 머신

RoblandTi 120 E

RoblandTi 120 E

소형 광고

Miechucino

Miechucino

7,961 km

GreCon Dimter OPTICUT 350 최적화기

WEINIGDimter Opticut 350 R

WEINIGDimter Opticut 350 R

소형 광고

독일

독일

8,700 km

브러시 연삭기 Fladder Gyro 300 VAC M

FladderFladder Gyro 300 VAC Ex.

FladderFladder Gyro 300 VAC Ex.

소형 광고

Askersund

Askersund

7,810 km

패널 톱

SchellingFH 6 430

SchellingFH 6 430

소형 광고

Roreto

Roreto

9,221 km

로트-1 엣지 밴딩 머신(레이저)

IMANovimat LASER System/I/R75/1110/R3

IMANovimat LASER System/I/R75/1110/R3

귀하의 광고가 성공적으로 삭제되었습니다

오류가 발생했습니다