디패널링/PCB 가공Systemtechnik Hölzer GmbH

Nutzentrenner LOW 4233 XL RD

디패널링/PCB 가공

Systemtechnik Hölzer GmbH

Nutzentrenner LOW 4233 XL RD

제조 연도

2026

상태

신규

위치

Kronberg im Taunus

사진은 보여줍니다

지도 표시

기계 정보

가격 및 위치

- 위치:

- Westerbachstraße 4, 61476 Kronberg im Taunus, Deutschland

전화하기

제안 세부 정보

- 광고 ID:

- A18369436

- 참조 번호:

- LOW4233 RD XL Leiterplatten Nutzentrenner

- 업데이트:

- 마지막 업데이트: 26.01.2026

설명

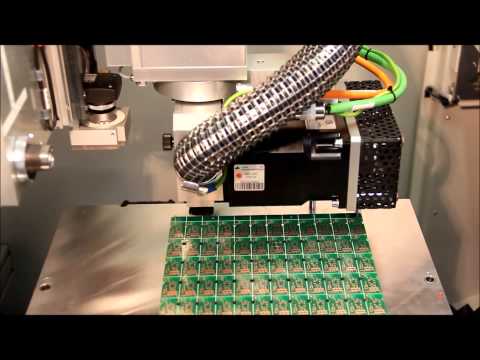

Semi-automatic depaneling / basic machine with parallel shuttle

The dynamic depaneling machine LOW 4322 XL is especially suited for medium to high product volumes and meets growing demands in the production process. Printed circuit board blanks of various materials are separated using low-dust and low-stress sawing and milling techniques with maximum product flexibility, precision and throughput. Highly dynamic linear motor axes, tools and grippers meet the highest quality requirements and guarantee the depaneling machine a long service life and high reliability.

Semiautomatic depaneling - solutions on demand

The LOW 4322 XL depanelling machine enables fast product changeover while maintaining short depanelling and handling times. The blank printed circuit board is inserted with a parallel shuttle, picked up and fixed with pin clamping technology and, if necessary, in combination with vacuum suction cups.

Made in Germany

The machine is equipped with:

Codpfxovuw R Rj Aa Sepu

- a shank and slice tool separation module on Z-axis (automatically rotatable 0-90)

- X-Y cross table module in linear motor technology with high-resolution measuring system

- 2-compartment loading module built as parallel shuttle, separated left and right with sliding doors

- Steel welding frame with two maintenance doors - left and right. ESD

- standard vision system base module for teach-in programming

- Working area is 520 x 480mm

- Automatic cutter length processing

- Remote maintenance/support via remote connection

- Touch IPC with Windows 10 Pro operating system

- Laser axis measurement incl. protocol

- Air ionization

- Cutter breakage control for end mills only

- Preparation for vacuum clamping technology

- ESD powder coating, RAL 9002, disc and sliding doors

Optionally a vacuum cleaner unit can be offered later.

The dynamic depaneling machine LOW 4322 XL is especially suited for medium to high product volumes and meets growing demands in the production process. Printed circuit board blanks of various materials are separated using low-dust and low-stress sawing and milling techniques with maximum product flexibility, precision and throughput. Highly dynamic linear motor axes, tools and grippers meet the highest quality requirements and guarantee the depaneling machine a long service life and high reliability.

Semiautomatic depaneling - solutions on demand

The LOW 4322 XL depanelling machine enables fast product changeover while maintaining short depanelling and handling times. The blank printed circuit board is inserted with a parallel shuttle, picked up and fixed with pin clamping technology and, if necessary, in combination with vacuum suction cups.

Made in Germany

The machine is equipped with:

Codpfxovuw R Rj Aa Sepu

- a shank and slice tool separation module on Z-axis (automatically rotatable 0-90)

- X-Y cross table module in linear motor technology with high-resolution measuring system

- 2-compartment loading module built as parallel shuttle, separated left and right with sliding doors

- Steel welding frame with two maintenance doors - left and right. ESD

- standard vision system base module for teach-in programming

- Working area is 520 x 480mm

- Automatic cutter length processing

- Remote maintenance/support via remote connection

- Touch IPC with Windows 10 Pro operating system

- Laser axis measurement incl. protocol

- Air ionization

- Cutter breakage control for end mills only

- Preparation for vacuum clamping technology

- ESD powder coating, RAL 9002, disc and sliding doors

Optionally a vacuum cleaner unit can be offered later.

이 광고들도 당신에게 관심이 있을 수 있습니다.

소형 광고

Matelica (MC)

Matelica (MC)

9,026 km

레이저 절단기 - 파이버 레이저 절단

PRIMA POWERPLATINO FIBER 1530

PRIMA POWERPLATINO FIBER 1530

소형 광고

Butzbach

Butzbach

8,725 km

머시닝센터

Starrag-HeckertHEC500D

Starrag-HeckertHEC500D

소형 광고

독일

독일

8,700 km

코팅 시스템 벤자콥 퍼펙트, OIR, 에어젯, UV

VenjakobVEN SPRAY and Drying, UV Line

VenjakobVEN SPRAY and Drying, UV Line

소형 광고

Borken

Borken

8,705 km

2 히터 라인 코팅 유리

Tool-TempHVD-G02

Tool-TempHVD-G02

소형 광고

Bad Waltersdorf

Bad Waltersdorf

8,565 km

유리 절단 리프트 테이블

Hegla

Hegla

소형 광고

Burghaun

Burghaun

8,651 km

해상 컨테이너

db-container20fuß

db-container20fuß

소형 광고

Herzogenrath

Herzogenrath

8,821 km

유리 드릴링 머신

SchramlTop Clear 13 Special- 4

SchramlTop Clear 13 Special- 4

소형 광고

Władysławowo

Władysławowo

7,904 km

유리

DIP TECHGlassJet NOVO

DIP TECHGlassJet NOVO

소형 광고

Butzbach

Butzbach

8,725 km

머시닝센터

Starrag-HeckertHEC400D

Starrag-HeckertHEC400D

소형 광고

Lleida

Lleida

9,866 km

수평 분체 도장 설비

WagnerHorizontal Painting line

WagnerHorizontal Painting line

귀하의 광고가 성공적으로 삭제되었습니다

오류가 발생했습니다