세로로 늘어뜨린EMAG

VT2-4

세로로 늘어뜨린

EMAG

VT2-4

EXW 고정 가격 부가세 별도

€19,895

제조 연도

2015

상태

중고

위치

Iași

사진은 보여줍니다

지도 표시

가격 및 위치

EXW 고정 가격 부가세 별도

€19,895

- 위치:

- Calea Chisinaului Nr. 132, C4 building, C1-parter, 1 floor, C2-parter, et.1, 700178 Iași, România

전화하기

제안 세부 정보

- 광고 ID:

- A20561170

- 참조 번호:

- B02

- 업데이트:

- 마지막 업데이트: 17.02.2026

설명

Technical characteristics:

Work Area

- Chuck diameter: 160 mm

- Maximum weight of chuck + workpiece: 45 kg

- Maximum workpiece diameter/height: 100/400 mm

- Distance spindle nose to origin of tailstock: 795.5 mm

- X1/X2 working stroke: 340 mm / Rapid traverse in X: 30 m/min

- Z1/Z2 stroke: 625 mm / Rapid traverse in Z: 30 m/min / Feed force: 18.7 kN

- Loading time: 5–6 sec

- Standard closed automation (number of loading nests by workpiece diameter): 14/(80–200 mm), 18/(30–160 mm), 30/(30–85 mm)

Main Spindle

- Spindle according to DIN 55026: Size KK5

- Maximum speed: 8,500 rpm

- Power at 100% / 40% duty cycle: 34 / 26.5 kW

- Torque at 100% / 40% duty cycle: 75 / 48 Nm

Tailstock

- Interface: MK3

- Clamping force: 120 N/bar

- Clamping stroke: 5 mm

Tool Holder with Motorized Tools

- Tool holders with cylindrical shank according to DIN 69880: 12 – BMT65

- Number of positions: 2 x 12 (1 gripper per turret)

- Maximum speed: 6,000 rpm

- Maximum torque at 10% duty cycle: 27 Nm, at 100% duty cycle: 14 Nm

Electrical Equipment

- Operating voltage: 400–480 V, 120 A

- Connected load: 45 kVA

Dimensions

- Total dimensions: Length = 5,300 mm with chip conveyor, Width = 1,760 mm, Height = 3,650 mm

- Weight: 7,500 kg

Main Features and Capabilities

- Vertical design: Optimized chip evacuation and automatic loading/unloading

- Control: GE Fanuc FS 32i

- High precision: Positioning accuracy on X and Z axes ±0.001 mm with Heidenhain linear scales

- Main spindle: High power and wide speed range

- Automation: EMAG O-type – Parts are loaded and unloaded automatically via integrated automation

- Live tools: Allows drilling and milling operations

- Tool life monitoring with sister tool management

- Chip conveyor, coolant unit, switchable dual cartridge filter, high pressure pump (15 bar)

- Fully enclosed working area, LED light in working area

- Documentation: Available both electronically and as hardcopy book

Machine Status: NOT WORKING

- X-axis drive

- Five electrical switches (Siemens)

- Hydraulic pump

- Operator panel (in stock, needs installation)

- Valve chiller

- Pressure switch for oiling unit

Bjdpfsxxtkwsx Ah Djcw

- Emulsion tank pump

- Four emulsion circuit switches (electrovalves)

- Pressure switch for hydraulic circuit

- Complete hydraulic block

이 광고는 자동으로 번역되었습니다. 번역 오류가 있을 수 있습니다.

Work Area

- Chuck diameter: 160 mm

- Maximum weight of chuck + workpiece: 45 kg

- Maximum workpiece diameter/height: 100/400 mm

- Distance spindle nose to origin of tailstock: 795.5 mm

- X1/X2 working stroke: 340 mm / Rapid traverse in X: 30 m/min

- Z1/Z2 stroke: 625 mm / Rapid traverse in Z: 30 m/min / Feed force: 18.7 kN

- Loading time: 5–6 sec

- Standard closed automation (number of loading nests by workpiece diameter): 14/(80–200 mm), 18/(30–160 mm), 30/(30–85 mm)

Main Spindle

- Spindle according to DIN 55026: Size KK5

- Maximum speed: 8,500 rpm

- Power at 100% / 40% duty cycle: 34 / 26.5 kW

- Torque at 100% / 40% duty cycle: 75 / 48 Nm

Tailstock

- Interface: MK3

- Clamping force: 120 N/bar

- Clamping stroke: 5 mm

Tool Holder with Motorized Tools

- Tool holders with cylindrical shank according to DIN 69880: 12 – BMT65

- Number of positions: 2 x 12 (1 gripper per turret)

- Maximum speed: 6,000 rpm

- Maximum torque at 10% duty cycle: 27 Nm, at 100% duty cycle: 14 Nm

Electrical Equipment

- Operating voltage: 400–480 V, 120 A

- Connected load: 45 kVA

Dimensions

- Total dimensions: Length = 5,300 mm with chip conveyor, Width = 1,760 mm, Height = 3,650 mm

- Weight: 7,500 kg

Main Features and Capabilities

- Vertical design: Optimized chip evacuation and automatic loading/unloading

- Control: GE Fanuc FS 32i

- High precision: Positioning accuracy on X and Z axes ±0.001 mm with Heidenhain linear scales

- Main spindle: High power and wide speed range

- Automation: EMAG O-type – Parts are loaded and unloaded automatically via integrated automation

- Live tools: Allows drilling and milling operations

- Tool life monitoring with sister tool management

- Chip conveyor, coolant unit, switchable dual cartridge filter, high pressure pump (15 bar)

- Fully enclosed working area, LED light in working area

- Documentation: Available both electronically and as hardcopy book

Machine Status: NOT WORKING

- X-axis drive

- Five electrical switches (Siemens)

- Hydraulic pump

- Operator panel (in stock, needs installation)

- Valve chiller

- Pressure switch for oiling unit

Bjdpfsxxtkwsx Ah Djcw

- Emulsion tank pump

- Four emulsion circuit switches (electrovalves)

- Pressure switch for hydraulic circuit

- Complete hydraulic block

이 광고는 자동으로 번역되었습니다. 번역 오류가 있을 수 있습니다.

이 광고들도 당신에게 관심이 있을 수 있습니다.

소형 광고

캐나다

캐나다

8,291 km

기어 성형기

GLEASON- PFAUTER100 S

GLEASON- PFAUTER100 S

소형 광고

Hattingen

Hattingen

8,725 km

수직 선반

EMAGVL2

EMAGVL2

소형 광고

Whanganui

Whanganui

9,733 km

보관 리프트

Kardex RemstarXP500 Shuttle

Kardex RemstarXP500 Shuttle

소형 광고

독일

독일

8,579 km

CNC 동시 터닝 센터

SpinnerTTS65-Triplex

SpinnerTTS65-Triplex

소형 광고

독일

독일

8,706 km

센터리스 - 원통 연삭기

JUNKERJupiter 500

JUNKERJupiter 500

소형 광고

Lebach

Lebach

8,897 km

진원도 게이지

Taylor HobsonTalyround 565T

Taylor HobsonTalyround 565T

소형 광고

독일

독일

8,579 km

CNC 터닝 및 밀링 센터

Niles-SimmonsN30/2500 MC

Niles-SimmonsN30/2500 MC

소형 광고

Weilerswist

Weilerswist

8,799 km

예비 부품

Kardex, Megamat, Hänel, NT, XP

Kardex, Megamat, Hänel, NT, XP

소형 광고

Korschenbroich

Korschenbroich

8,772 km

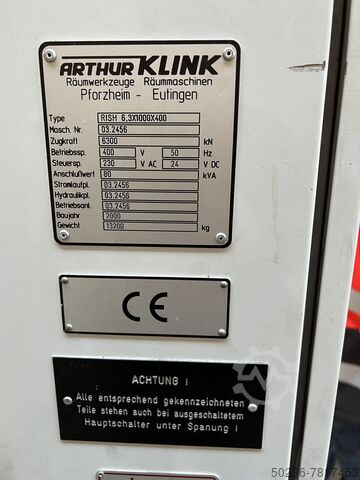

CNC 내부 브로칭 머신

Arthur KlinkRISH 6.3X1000X400

Arthur KlinkRISH 6.3X1000X400

소형 광고

독일

독일

8,706 km

기어 호빙 머신 - 수직

LIEBHERRLC200

LIEBHERRLC200

귀하의 광고가 성공적으로 삭제되었습니다

오류가 발생했습니다