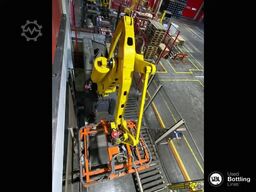

디팔렛타이저FANUC

M-410 iB 160

디팔렛타이저

FANUC

M-410 iB 160

제조 연도

2003

상태

중고

위치

Fumane (Verona)

사진은 보여줍니다

지도 표시

기계 정보

가격 및 위치

- 판매자 위치:

- Via Incisa 1, 37022 Fumane (Verona), 이탈리아

전화하기

제안 세부 정보

- 광고 ID:

- A18007671

- 참조 번호:

- DEPAL31

- 업데이트:

- 마지막 업데이트: 16.12.2024

설명

Used Robot Depalletizer Fanuc 2003 – The Ultimate Solution for Depalletizing Operations

Are you looking for a reliable and efficient robot depalletizer for your business operations? Look no further than the 2003 Fanuc Robot Depalletizer model M-410 iB 160. Equipped with a pick-up head for cardboard and an available base, this depalletizer is designed specifically for depalletizing tasks.

With its intelligent cable routing inside the hollow wrist, high operating speeds, and high inertia and wrist moments, this machine can handle large grippers and heavy payloads with ease. Its 6-axis control servo gripper provides better adaptability in handling products of different sizes.

Operating within an optimized workspace and with high vertical travel, this robot can depalletize products up to a height of almost 2.7 meters. The integrated base and controller in the pedestal (or the available non-pedestal version) save floor space and simplifies transportation and installation.

Upgrade your depalletizing operations with the 2003 Fanuc Robot Depalletizer – the ultimate solution for efficient and effective depalletizing. With a gripper head for depalletizing one layer of bottles at a time (inflatable)

Botte holding system:

This Fanuc robot depalletizer has a particular bottle gripper:

Use the neck bottle gripping system using inflatable bars.

This system helps to process shaped bottles and therefore allows them to be deposited on the loading table with irregular bottles.

The classic push system has this limitation, it cannot process bottles other than round ones.

Godpfx Aasvgvx Dj Sobh

But the Fanuc robot depalletizer has a speed of 200 layers per hour to a maximum of 12,000 BPH.

Another important feature is the space required to work with that equipment, compared to traditional systems at least 50% of the usable surface is saved; for the same performance, a robot is always preferable, also because being able to change the bottle gripper, all types of bottles can be processed with very high peak loads.

Are you looking for a reliable and efficient robot depalletizer for your business operations? Look no further than the 2003 Fanuc Robot Depalletizer model M-410 iB 160. Equipped with a pick-up head for cardboard and an available base, this depalletizer is designed specifically for depalletizing tasks.

With its intelligent cable routing inside the hollow wrist, high operating speeds, and high inertia and wrist moments, this machine can handle large grippers and heavy payloads with ease. Its 6-axis control servo gripper provides better adaptability in handling products of different sizes.

Operating within an optimized workspace and with high vertical travel, this robot can depalletize products up to a height of almost 2.7 meters. The integrated base and controller in the pedestal (or the available non-pedestal version) save floor space and simplifies transportation and installation.

Upgrade your depalletizing operations with the 2003 Fanuc Robot Depalletizer – the ultimate solution for efficient and effective depalletizing. With a gripper head for depalletizing one layer of bottles at a time (inflatable)

Botte holding system:

This Fanuc robot depalletizer has a particular bottle gripper:

Use the neck bottle gripping system using inflatable bars.

This system helps to process shaped bottles and therefore allows them to be deposited on the loading table with irregular bottles.

The classic push system has this limitation, it cannot process bottles other than round ones.

Godpfx Aasvgvx Dj Sobh

But the Fanuc robot depalletizer has a speed of 200 layers per hour to a maximum of 12,000 BPH.

Another important feature is the space required to work with that equipment, compared to traditional systems at least 50% of the usable surface is saved; for the same performance, a robot is always preferable, also because being able to change the bottle gripper, all types of bottles can be processed with very high peak loads.

이 광고들도 당신에게 관심이 있을 수 있습니다.

소형 광고

Fumane (Verona)

Fumane (Verona)

8,980 km

팔레타이저

FANUCM-410 iB 160

FANUCM-410 iB 160

소형 광고

Veliko Tarnovo

Veliko Tarnovo

8,234 km

트레이 실러

SEALPAC800

SEALPAC800

소형 광고

Braunschweig

Braunschweig

8,485 km

열성형 / 블리스터 포장 기계

AUTOVAKM320

AUTOVAKM320

소형 광고

Urk

Urk

8,703 km

열성형기

WebomaticAPS ML 7100

WebomaticAPS ML 7100

소형 광고

Romano di Lombardia

Romano di Lombardia

9,046 km

자수

BAITHE VISION 2

BAITHE VISION 2

소형 광고

Krotoszyn

Krotoszyn

8,170 km

패커/포장기

MultivacR230

MultivacR230

소형 광고

Ukmergė

Ukmergė

7,548 km

자동 팔레트 디스펜서, 스태커

UMP TechnikaPD-10

UMP TechnikaPD-10

소형 광고

Misterton

Misterton

8,929 km

진공 충전기

RiscoRS1040 MAS

RiscoRS1040 MAS

소형 광고

Menslage

Menslage

8,591 km

GM Gera ARCADE GEL 6 RV1-VL 362/110-30 병 세척기 (2010년)

GM GeraFlaschenreinigungsmaschine

GM GeraFlaschenreinigungsmaschine

소형 광고

Ystad

Ystad

8,101 km

열성형기

COLIMATICTHERA

COLIMATICTHERA

귀하의 광고가 성공적으로 삭제되었습니다

오류가 발생했습니다