물, 오일, 비누, AdBlue 충전기PROTON EE-ELEKTRONIKA d.o.o

XFR1000

물, 오일, 비누, AdBlue 충전기

PROTON EE-ELEKTRONIKA d.o.o

XFR1000

제조 연도

2025

상태

신규

위치

Šašinovec

사진은 보여줍니다

지도 표시

기계 정보

가격 및 위치

- 위치:

- Krcevina 4, 10360 Soblinec, Hrvatska

전화하기

기술 세부 사항

- 총 폭:

- 2,400 mm

- 총 길이:

- 15,000 mm

- 총 높이:

- 2,800 mm

- 압력:

- 8 바

- 동력:

- 10.9 킬로와트 (14.82 마력)

- 공차 중량:

- 6,400 kg

- 입력 전압:

- 400 V

- 충전 중량(최소):

- 200 g

- 최대 충전 중량:

- 5,000 g

제안 세부 정보

- 광고 ID:

- A17231422

- 업데이트:

- 마지막 업데이트: 25.09.2025

설명

XFR 1000

Liquid Media Filling Line

Cgodpfjuq Nv Tsx Aa Ssn

A fully automated liquid media filling line featuring robotic capping, automated handle placement, dual-sided labelling, optical quality control, and pallet wrapping.

An end-to-end solution covering the entire process, from bottle blowing to the palletizing and wrapping of filled bottles.

XFR LIQUILOAD

It enables optimal filling speeds for bottles of varying characteristics and liquids of different viscosities.

The machine’s easy configuration for different bottle types and corresponding liquids ensures quick adaptation to market demands.

• Capability to increase the number of nozzles

• Nozzles designed to prevent foaming of the liquid

• 800 to 4,000 filled bottles per hour

• Servo-driven nozzle positioning

• Easy configuration of new programs

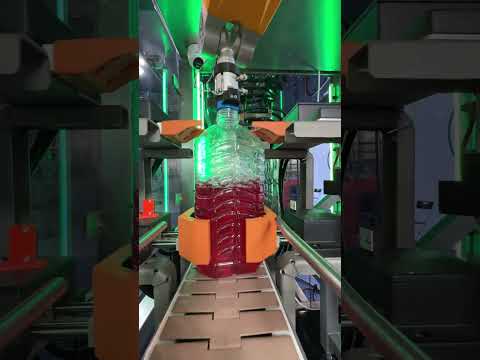

XFR BOTTLELOCK

The machine segment performs fully automated capping of filled bottles.

Designed to accommodate various cap types, simplifying machine adjustments for seamless operation.

• Cap type adaptability

• Robotic bottle capping

• Optical inspection

• 800 to 2,000 capped bottles per hour

XFR HANDLEGRIP

The automatic robotic placement of handles on bottles, while they move continuously towards the labeling machine, ensures seamless and uninterrupted operation.

• Adaptability to different handle types

• Robotic handle application on bottles

• Optical inspection for handle orientation verification

• Capability to attach handles with a funnel

XFR LABELFLOW

The machine applies the appropriate labels to both sides of the bottle, creating a finished appearance.

In the next phase, the labelled bottles undergo optical inspection.

• HERMA labelling system

• Simplified label type changeover

• Servo-driven for enhanced labeling precision

• Monitoring of remaining labels with operator alerts

OPTIONAL PARTS:

1. OPTICAL INSPECTION

Industrial cameras with integrated lighting and pneumatic ejection system.

2. PICK AND PLACE ROBOT

6-axis robot equipped with a 160 kg gripper for the current handling of 8 bottles onto a Euro pallet.

3. PALLETIZING

Palletizer with automatic pallet feeding via a roller conveyor to the bottle stacking area.

4. PALLET WRAPPING

The automatic pallet wrapper applies stretch film to palletized products, securing them for easier and safer transport.

5. FINISHED GOODS STORAGE

Finished pallets are transported to the warehouse via a metal roller conveyor.

6. REMOTE CUSTOMER SUPPORT

We provide remote support to ensure optimal machine performance.

7. ADDITIONAL OPTIONS

Automated data integration with ERP systems; RFID login; NFC detection of parts and tools; magnetically mounted tools.

8. MACHINE CONFIGURATION

Segments can operate independently or as an integrated solution, depending on the client's specific needs.

Proton EE-Elektronika d.o.o.

MachinFlex d.o.o.

Liquid Media Filling Line

Cgodpfjuq Nv Tsx Aa Ssn

A fully automated liquid media filling line featuring robotic capping, automated handle placement, dual-sided labelling, optical quality control, and pallet wrapping.

An end-to-end solution covering the entire process, from bottle blowing to the palletizing and wrapping of filled bottles.

XFR LIQUILOAD

It enables optimal filling speeds for bottles of varying characteristics and liquids of different viscosities.

The machine’s easy configuration for different bottle types and corresponding liquids ensures quick adaptation to market demands.

• Capability to increase the number of nozzles

• Nozzles designed to prevent foaming of the liquid

• 800 to 4,000 filled bottles per hour

• Servo-driven nozzle positioning

• Easy configuration of new programs

XFR BOTTLELOCK

The machine segment performs fully automated capping of filled bottles.

Designed to accommodate various cap types, simplifying machine adjustments for seamless operation.

• Cap type adaptability

• Robotic bottle capping

• Optical inspection

• 800 to 2,000 capped bottles per hour

XFR HANDLEGRIP

The automatic robotic placement of handles on bottles, while they move continuously towards the labeling machine, ensures seamless and uninterrupted operation.

• Adaptability to different handle types

• Robotic handle application on bottles

• Optical inspection for handle orientation verification

• Capability to attach handles with a funnel

XFR LABELFLOW

The machine applies the appropriate labels to both sides of the bottle, creating a finished appearance.

In the next phase, the labelled bottles undergo optical inspection.

• HERMA labelling system

• Simplified label type changeover

• Servo-driven for enhanced labeling precision

• Monitoring of remaining labels with operator alerts

OPTIONAL PARTS:

1. OPTICAL INSPECTION

Industrial cameras with integrated lighting and pneumatic ejection system.

2. PICK AND PLACE ROBOT

6-axis robot equipped with a 160 kg gripper for the current handling of 8 bottles onto a Euro pallet.

3. PALLETIZING

Palletizer with automatic pallet feeding via a roller conveyor to the bottle stacking area.

4. PALLET WRAPPING

The automatic pallet wrapper applies stretch film to palletized products, securing them for easier and safer transport.

5. FINISHED GOODS STORAGE

Finished pallets are transported to the warehouse via a metal roller conveyor.

6. REMOTE CUSTOMER SUPPORT

We provide remote support to ensure optimal machine performance.

7. ADDITIONAL OPTIONS

Automated data integration with ERP systems; RFID login; NFC detection of parts and tools; magnetically mounted tools.

8. MACHINE CONFIGURATION

Segments can operate independently or as an integrated solution, depending on the client's specific needs.

Proton EE-Elektronika d.o.o.

MachinFlex d.o.o.

이 광고들도 당신에게 관심이 있을 수 있습니다.

소형 광고

Viersen

Viersen

8,776 km

열병합 발전소

MWMETW 800 EG-CO-KA

MWMETW 800 EG-CO-KA

소형 광고

Kirchheimbolanden

Kirchheimbolanden

8,819 km

원형 및 사각형 용기용 라벨링 시스템

Weidmann Maschinen EtikettiermaschineFL-800

Weidmann Maschinen EtikettiermaschineFL-800

소형 광고

Δράμα

Δράμα

8,458 km

오프셋 인쇄 유형

ShinoharaSHINOHARA 75

ShinoharaSHINOHARA 75

소형 광고

Rīga

Rīga

7,487 km

자동 양배추 코어 드릴 KU-2400

Alistar EuropeKU-2400

Alistar EuropeKU-2400

소형 광고

Tata

Tata

8,397 km

이그젠터 프레스 AIDA NC2-250, 250톤

AIDA NC1-250250ton

AIDA NC1-250250ton

소형 광고

Kreuzau

Kreuzau

8,809 km

프로세스 플랜트

FrymaMZM / VK 50

FrymaMZM / VK 50

소형 광고

Raszyn

Raszyn

7,948 km

튜브 충전기, 튜브 충전 기계

Jedlinski PackagingJTB-40

Jedlinski PackagingJTB-40

소형 광고

Schorfheide

Schorfheide

8,289 km

고정식 혼합 플랜트

Sonstige/OtherFrumecar Fastmix DIE BETONTANKSTELLE

Sonstige/OtherFrumecar Fastmix DIE BETONTANKSTELLE

소형 광고

Jüri

Jüri

7,306 km

디바커

Valon Kone OYVK-550-Combi 2R/480(620)

Valon Kone OYVK-550-Combi 2R/480(620)

소형 광고

Ostrołęka

Ostrołęka

7,850 km

우유 및 유제품 생산

MargoPasteryzator

MargoPasteryzator

귀하의 광고가 성공적으로 삭제되었습니다

오류가 발생했습니다