CNC 머시닝 센터SCM

Morbidelli M100

CNC 머시닝 센터

SCM

Morbidelli M100

제조 연도

2023

상태

중고

위치

Nattheim

사진은 보여줍니다

지도 표시

기계 정보

가격 및 위치

- 위치:

- Daimlerstr. 21, 89564 Nattheim, DE

전화하기

제안 세부 정보

- 광고 ID:

- A20924487

- 참조 번호:

- CC-K-25008

- 업데이트:

- 마지막 업데이트: 16.01.2026

설명

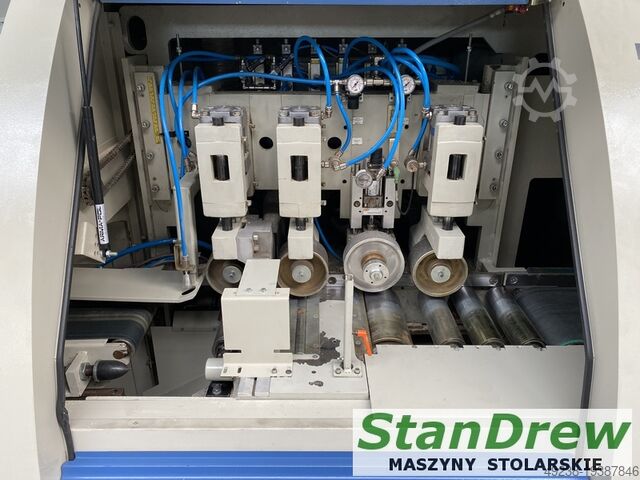

Exhibition Machine Garbsen CNC-CONTROLLED MACHINING CENTER morbidelli m100 Drilling and Milling Made for You! This numerically controlled machining center is equipped with a comprehensive range of accessories and tools for milling and drilling, enabling it to meet every requirement in the field of wood processing. Highly efficient – with drilling spindles reaching up to 8,000 rpm – and featuring technology that includes the most robust spindle available on the market, offering more than 1,000 hours of maintenance-free operation. Fully equipped – the suction cups can be individually configured with the TV FLEX worktable to adapt the machine precisely to your requirements. Easy and intuitive programming thanks to the integrated Cad-Cam MAESTRO CNC software. User-friendly operation is ensured by the lowered machine frame, which provides unrestricted access to the worktable at all times. The control cabinet and vacuum pump are integrated into the machine base, and the PRO SPACE variant requires no additional structural safety measures.

Robust Construction The supporting structure consists of an especially sturdy monolithic steel base, ribbed for stability and durability. The extra-wide bearing surface is purpose-designed to provide the machine with stability, ensuring constant precision in all working conditions. Anchoring to the floor is not required. The base forms a large, solid foundation for the moving gantry: the working unit is equipped with a balanced, stable, and resilient support, withstanding the highest stress, which ensures superior quality performance and greater accuracy. The moving gantry is a solid single piece anchored to the base, running on high-quality prismatic guides with ball bearing carriages. The working unit is mounted to this and moves along the Y and Z axes on prismatic guides with ball bearing carriages as well. Movement of the lower movable unit (X-axis) and the working unit along the gantry (Y-axis) is driven by a helical toothed rack and pinion system; this produces greater tooth-by-tooth thrust, achieving higher acceleration and increased speed on the X and Y axes. The specially designed helical gearing ensures reduced wear of mechanical components and quieter operation.

The vertical Z-axis is driven by a recirculating ball screw, providing perfect balance under dynamic load and withstanding significant acceleration and deceleration. The main milling unit is directly coupled to the Z-axis carriage, enabling superior surface finish quality as vibrations are completely eliminated. Travel along the X-Y-Z axes is achieved with brushless motors powered by static inverters. These provide:

- Reduced processing times due to improved acceleration

- Increased positioning accuracy due to high-resolution encoders

- Elimination of setup tasks at machine startup thanks to absolute encoders

- Elimination of general maintenance tasks, as the brushless system has no brushes

Axis movement management and general operation of the working elements...

Hfodpfxjx Twcij Abhob

이 광고는 자동으로 번역되었습니다. 번역 오류가 있을 수 있습니다.

Robust Construction The supporting structure consists of an especially sturdy monolithic steel base, ribbed for stability and durability. The extra-wide bearing surface is purpose-designed to provide the machine with stability, ensuring constant precision in all working conditions. Anchoring to the floor is not required. The base forms a large, solid foundation for the moving gantry: the working unit is equipped with a balanced, stable, and resilient support, withstanding the highest stress, which ensures superior quality performance and greater accuracy. The moving gantry is a solid single piece anchored to the base, running on high-quality prismatic guides with ball bearing carriages. The working unit is mounted to this and moves along the Y and Z axes on prismatic guides with ball bearing carriages as well. Movement of the lower movable unit (X-axis) and the working unit along the gantry (Y-axis) is driven by a helical toothed rack and pinion system; this produces greater tooth-by-tooth thrust, achieving higher acceleration and increased speed on the X and Y axes. The specially designed helical gearing ensures reduced wear of mechanical components and quieter operation.

The vertical Z-axis is driven by a recirculating ball screw, providing perfect balance under dynamic load and withstanding significant acceleration and deceleration. The main milling unit is directly coupled to the Z-axis carriage, enabling superior surface finish quality as vibrations are completely eliminated. Travel along the X-Y-Z axes is achieved with brushless motors powered by static inverters. These provide:

- Reduced processing times due to improved acceleration

- Increased positioning accuracy due to high-resolution encoders

- Elimination of setup tasks at machine startup thanks to absolute encoders

- Elimination of general maintenance tasks, as the brushless system has no brushes

Axis movement management and general operation of the working elements...

Hfodpfxjx Twcij Abhob

이 광고는 자동으로 번역되었습니다. 번역 오류가 있을 수 있습니다.

이 광고들도 당신에게 관심이 있을 수 있습니다.

소형 광고

Nattheim

Nattheim

8,776 km

CNC 머시닝 센터

SCMMorbidelli M 100 (3-Achs)

SCMMorbidelli M 100 (3-Achs)

소형 광고

Juszczyn

Juszczyn

8,175 km

경사 스핀들 밀링 머신

Panhans240A

Panhans240A

소형 광고

Böblingen

Böblingen

8,844 km

테이블 밀링 머신

Holzkraftminimax t 45c Tischfräse

Holzkraftminimax t 45c Tischfräse

소형 광고

Miechucino

Miechucino

7,961 km

GreCon Dimter OPTICUT 350 최적화기

WEINIGDimter Opticut 350 R

WEINIGDimter Opticut 350 R

소형 광고

Nattheim

Nattheim

8,776 km

CNC 머시닝 센터

Format 4Profit H200 13.33 4-Achs

Format 4Profit H200 13.33 4-Achs

소형 광고

Nattheim

Nattheim

8,776 km

CNC 머시닝 센터

SCM morbidelliM 400

SCM morbidelliM 400

소형 광고

Nattheim

Nattheim

8,776 km

스탠딩 패널 톱

Putsch-MeniconiSVP 950 M ECO

Putsch-MeniconiSVP 950 M ECO

소형 광고

Nattheim

Nattheim

8,776 km

페인트 미스트 추출 벽

HöckerPaint Star 3500

HöckerPaint Star 3500

소형 광고

Scerne

Scerne

9,009 km

수직 패널 톱

Putsch MeniconiUniver

Putsch MeniconiUniver

소형 광고

Egenhofen

Egenhofen

8,760 km

스위블 스핀들 밀링 머신

RoblandTi 120 E

RoblandTi 120 E

귀하의 광고가 성공적으로 삭제되었습니다

오류가 발생했습니다