고속 과립기ZERMA

GST 250/300

고속 과립기

ZERMA

GST 250/300

VB 부가세 별도

€16,200

제조 연도

2025

상태

신규

위치

Buchholz in der Nordheide

사진은 보여줍니다

지도 표시

기계 정보

가격 및 위치

VB 부가세 별도

€16,200

- 위치:

- Vaenser Weg 12, 21244 Buchholz in der Nordheide, Deutschland

전화하기

제안 세부 정보

- 광고 ID:

- A13548235

- 업데이트:

- 마지막 업데이트: 03.05.2025

설명

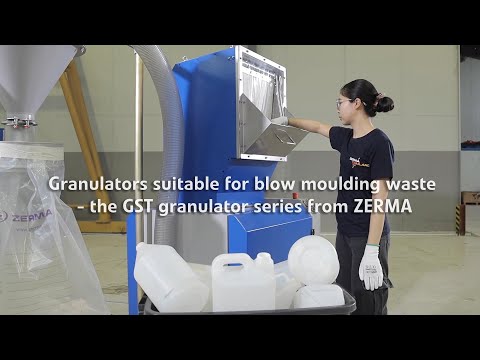

Size reduction of large-volume blow molded parts as well as start and end pieces

In a compact redesign, the best features of the proven GST and GSC series have been integrated, with special emphasis on weight, handling and energy efficiency.

These compact granulators are equipped with complete sound insulation, resulting in extremely quiet operation. The granulators are available with 250 mm rotor diameters and widths from 300, 450 to 600 mm. The curved rear wall of the cutting chamber ensures aggressive material intake and prevents material jams. As with all ZERMA granulators, the rotor and stator knives are adjustable outside the machine, reducing downtime for maintenance.

The highly tangential, curved rear wall of the cutting chamber, combined with the aggressive open rotor design, ensures reliable material pickup and minimizes the risk of jams.

The compact granulators are suitable for use in blow molding operations. They are suitable for recycling e.g. voluminous parts such as bottles, canisters, crates. Due to the low feeding height, the machines can be easily fed with material by hand or by a small conveyor belt. The low noise emission and the small footprint make the granulator a perfect solution for inline size reduction

Kjdpfx Asp Sr Anjd Hsfa

Optional rear panel with higher stator knife M version:

The feed method with a higher positioned stator knife is better suited for thicker walled and more compact parts, such as injection molded parts, profiles, plates, etc. Due to the cutting geometry and the lower aggressiveness of the rotor, a high quality regrind is obtained regardless of the material type or shape, such as injection molded parts, profiles, plates, etc.

Control system and control panel:

The integrated control system and control panel not only comply with all applicable safety regulations, but can also be customized to meet specific requirements. In addition, peripheral equipment such as infeed conveyors, metal detection and unloading systems can be seamlessly integrated into the machine's control system. For improved efficiency, an optional intelligent energy saving function is also available that reduces power consumption during idle periods and can automatically start and stop the system based on the status of upstream machines.

Standard configuration with blower, power consumption 0.75 kW and 400 er cyclone

Rotor diameter (mm) 250

Rotor width (mm) 300

Drive (kW) 7.5

Number of rotor blades 3 x 1

Number of stator knives 2

Screen perforation (mm) > 6

Weight approx. (kg) 950

Feed opening (mm) 380 x 300

Feed opening option of M version (mm) 295 x 300

이 광고는 자동으로 번역되었습니다. 번역 오류가 있을 수 있습니다.

In a compact redesign, the best features of the proven GST and GSC series have been integrated, with special emphasis on weight, handling and energy efficiency.

These compact granulators are equipped with complete sound insulation, resulting in extremely quiet operation. The granulators are available with 250 mm rotor diameters and widths from 300, 450 to 600 mm. The curved rear wall of the cutting chamber ensures aggressive material intake and prevents material jams. As with all ZERMA granulators, the rotor and stator knives are adjustable outside the machine, reducing downtime for maintenance.

The highly tangential, curved rear wall of the cutting chamber, combined with the aggressive open rotor design, ensures reliable material pickup and minimizes the risk of jams.

The compact granulators are suitable for use in blow molding operations. They are suitable for recycling e.g. voluminous parts such as bottles, canisters, crates. Due to the low feeding height, the machines can be easily fed with material by hand or by a small conveyor belt. The low noise emission and the small footprint make the granulator a perfect solution for inline size reduction

Kjdpfx Asp Sr Anjd Hsfa

Optional rear panel with higher stator knife M version:

The feed method with a higher positioned stator knife is better suited for thicker walled and more compact parts, such as injection molded parts, profiles, plates, etc. Due to the cutting geometry and the lower aggressiveness of the rotor, a high quality regrind is obtained regardless of the material type or shape, such as injection molded parts, profiles, plates, etc.

Control system and control panel:

The integrated control system and control panel not only comply with all applicable safety regulations, but can also be customized to meet specific requirements. In addition, peripheral equipment such as infeed conveyors, metal detection and unloading systems can be seamlessly integrated into the machine's control system. For improved efficiency, an optional intelligent energy saving function is also available that reduces power consumption during idle periods and can automatically start and stop the system based on the status of upstream machines.

Standard configuration with blower, power consumption 0.75 kW and 400 er cyclone

Rotor diameter (mm) 250

Rotor width (mm) 300

Drive (kW) 7.5

Number of rotor blades 3 x 1

Number of stator knives 2

Screen perforation (mm) > 6

Weight approx. (kg) 950

Feed opening (mm) 380 x 300

Feed opening option of M version (mm) 295 x 300

이 광고는 자동으로 번역되었습니다. 번역 오류가 있을 수 있습니다.

이 광고들도 당신에게 관심이 있을 수 있습니다.

소형 광고

Gladbeck

Gladbeck

8,723 km

디캔터 배수 시스템

HillerDECAPRESS DP45-422 MOBIL

HillerDECAPRESS DP45-422 MOBIL

소형 광고

Salzweg

Salzweg

8,606 km

치과용 밀링 머신

SchützTizian Cut 5 Dental

SchützTizian Cut 5 Dental

소형 광고

Düsseldorf

Düsseldorf

8,760 km

교정 프레스 유압 프레스 150톤

TigermetalWerkstattpresse 150 Tonnen WH150

TigermetalWerkstattpresse 150 Tonnen WH150

소형 광고

Sinsheim

Sinsheim

8,807 km

제림기

NEUE HERBOLDSM 300/500-S3-3 EDELSTAHL/STAINLESS STEE

NEUE HERBOLDSM 300/500-S3-3 EDELSTAHL/STAINLESS STEE

소형 광고

Schwieberdingen

Schwieberdingen

8,825 km

스위스형 자동선반

CITIZENL20 VIII

CITIZENL20 VIII

소형 광고

Breginj

Breginj

8,780 km

자동 봉재 선반

CitizenL20

CitizenL20

소형 광고

Radeberg

Radeberg

8,400 km

헬리컬 베벨 감속기 산업용 감속기

ASUG Penig FlenderTGL 21815 10LA1 280/400x80

ASUG Penig FlenderTGL 21815 10LA1 280/400x80

소형 광고

Soerendonk

Soerendonk

8,813 km

기어 유닛 / 기어박스

Flender / SiemensK2S-2,5

Flender / SiemensK2S-2,5

소형 광고

Rzeszów

Rzeszów

8,018 km

베이커리 카트, 교정 카트

58x78

58x78

소형 광고

Hessisch Lichtenau

Hessisch Lichtenau

8,614 km

ISBM 라인 = 사출 스트레치 블로우 성형; 일회용 PET 병용 스트레치 블로우 기계, 생산

ETEK / GF-IndustriesSupra 800 sv 1

ETEK / GF-IndustriesSupra 800 sv 1

귀하의 광고가 성공적으로 삭제되었습니다

오류가 발생했습니다